Product Description

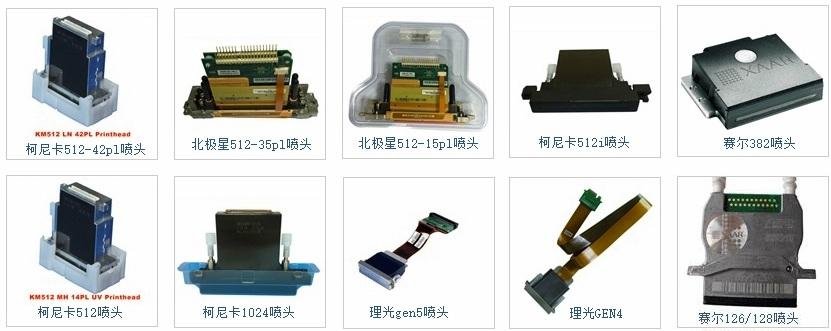

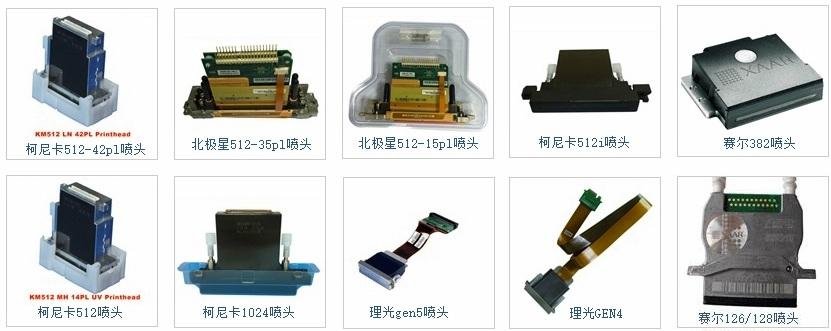

Our company was founded in 1998, the investment of more than 8 million yuan, is a professional hot foaming photo machine nozzle, piezoelectric photo machine nozzle, jet printing machine nozzle and other wide-frame photo machine supplies sales and services of high-tech enterprises. With 2000 square meters of enterprise building and independent import and export rights, more than 100 employees. Long-term wholesale all kinds of new original indoor outdoor photo machine nozzle, UV tablet nozzle, digital printing machine nozzle, muto piezoelectric nozzle/Mimaki, Roland/Epson Epson, konica/ricoh/kyocera/Toshiba/seiko/self/Polaris printing machine nozzle, ink sac, pictorial machine accessories such as advertising equipment supplies, imports and exports more than 5000 ten thousand yuan. The company is located in guangzhou Economic development Zone, China, is a collection of science, industry, trade combination of photo machine nozzle marketing enterprises. The company has long-term service institutions in Hong Kong, Taiwan and Japan to better meet the market demand of photo machine nozzle at home and abroad, and the product sales field covers the whole Southeast Asian market.

Tips: During holidays, if the printing equipment is not turned on for a long time, be sure to take corresponding maintenance measures for the printer nozzle. Can use the original sprinkler protection liquid, pour some on the machine ink pad, can effectively prevent the ink dry ink caused by the nozzle aging blockage; In addition, the nozzle can be taken down directly, clean and then sealed storage. As we all know, the print head is not guaranteed and expensive, hope our customers must adhere to the daily maintenance of the nozzle.

Common factors of UV flatbed printer nozzle damage are as follows:

One, the word car failed to reset in time

UV flatbed printer after the end of work, the car failed to reset to the position of the cleaning unit in time. At the same time the ink pad can not top to seal the nozzle. As a result, the nozzle is not in a constant humidity and constant pressure environment, exposed to the air for a long time, the UV ink at the nozzle hole dries up, causing the nozzle blockage.

Two, the printing process of the nozzle friction scratching

UV flatbed printer scratches the nozzle in the printing process, the main factor is the material printed. Some materials expand when heated. This is why some customers use UV flatbed printers, at the beginning of the printing, the height of the nozzle is adjusted, but the middle of the rub to the nozzle. The reason is that the material expands when heated by UV lamps used to cure ink.

Three, the reason for UV ink

Some UV flatbed printer users, in order to figure cheap and save printing costs, from the market to buy some substandard ink. As everyone knows, the low price ink on the market has great hidden dangers. It is recommended to choose the UV ink matched by the UV flatbed printer manufacturer, which is matched with the machine after strict testing in advance, and the UV ink pigment particle fineness, corrosion, fluency, UV molecular photosensitivity in the ink is completely suitable. And UV ink on the market, in these aspects may not be suitable. Therefore, it is easy to cause nozzle loss or even scrap nozzle because of UV ink.

Four, printing reflective material

The principle of UV flatbed printer printing depends on the spectrum emitted by the UV lamp and UV molecules in the UV ink to produce a contraction reaction, and then achieve the effect of curing. But some reflective materials (such as stainless steel, mirrors, etc.) are not suitable for printing. The reason is that when printing,UV light irradiation on the nozzle will lead to UV ink curing at the nozzle hole, resulting in the nozzle is often blocked.

UV flatbed printer nozzle daily maintenance method (such as the following) :

1. Prevent oxidation of the nozzle socket and forbid direct contact with the socket by hand.

2, to prevent the nozzle pinhole plug, the installation process must pay attention to whether the socket is aligned, and then insert.

3. Prevent the sprinkler circuit from burning out and keep the sprinkler working in a good heat dissipation environment.

4. To prevent damage caused by static electricity, static electricity must be eliminated when operating the nozzle or contacting the nozzle board

5. If there is a break in the printhead, it is necessary to clean the printhead. If the printhead is seriously blocked, you can pump ink first.

6, the use of weak solvent ink printer is easy to encounter plug trouble, plug is the cause of ink solvent volatilization, ink particles condense in the nozzle, resulting in nozzle blockage. The second is that the ink has impurities, or react with a solvent to generate foreign bodies, blocked in the nozzle. The way to prevent it is to use a filter device, the cartridge can not enter impurities, and often maintain the nozzle. Medium cleaning: Before cleaning, fill the syringe with cleaning tube with special cleaning liquid; When cleaning, unplug the ink tube first, and then insert the cleaning tube into the ink mouth of the nozzle, so that the cleaning liquid with pressure enters the nozzle from the ink tube until the ink is washed clean in the nozzle. Deep cleaning: nozzle blockage serious nozzle must be removed and thoroughly cleaned, can soak for a long time (dissolve the ink condensation nozzle), and then use special nozzle cleaning agent for cleaning, (in the nozzle preservation, loading and unloading, cleaning, soaking to be careful; If scratched by hard objects, will lead to the nozzle's rays are not straight or scrapped).

7, nozzle blockage is generally the result of long-term accumulation, the user must always keep the nozzle smooth when using.

8, the sprinkler head should be checked regularly, the sprinkler head in use should be maintained regularly, and the sprinkler head can be removed and sealed when not in use for a long time.

9, choose UV printer should pay attention to, whether the machine itself has the function of detecting cleaning nozzle, automatic cleaning eliminates the trouble of manual operation.

10, UV flat plate printer head belongs to high precision consumables products, there is no warranty and the price is expensive on the market, so the user must be careful operation and seriously do a good job in daily maintenance of the nozzle can effectively reduce the nozzle failure.

Product Image